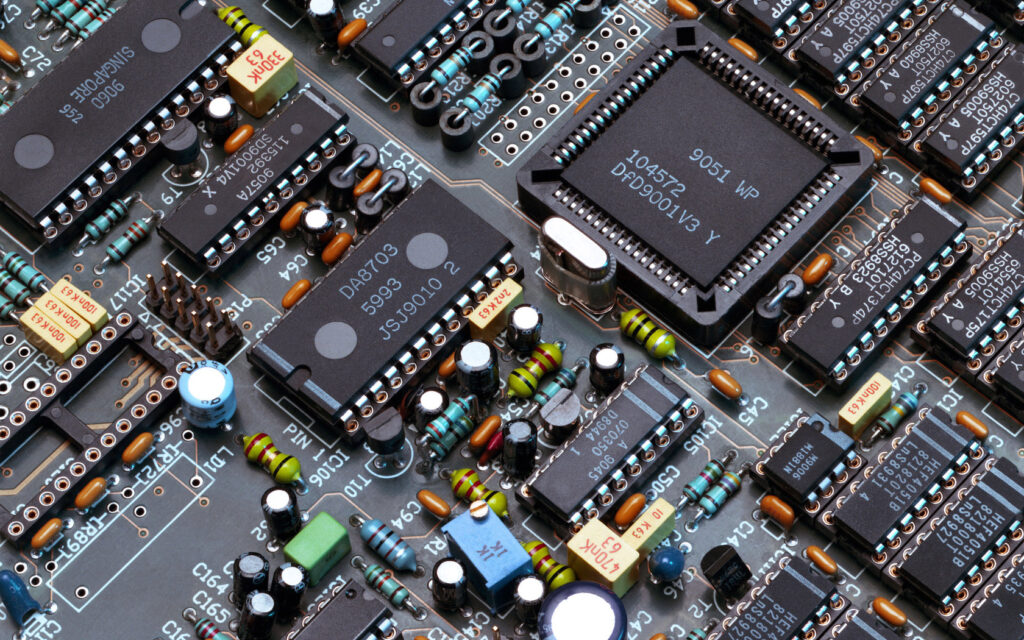

DIP lead mounting (manual soldering) is used for small batches of prototype boards, when soldering THT components after installing SMD components on an automatic assembly line. The advantages of this type of assembly include the ability to perform assembly of any degree of complexity.

The company employs assemblers with 10 to 20 years of experience in this speciality. The assembly area is equipped with soldering and repair stations from leading global manufacturers, which ensure stable temperature maintenance, i.e. high quality installation. The workstations are equipped with antistatic protection.

We carry out surface mount SMD assembly of printed circuit boards of any complexity, as well as a full cycle of electronic device development.

Read the requirements to place your order, or contact us for more information.

Contact us now

or send us a request and we will contact you: